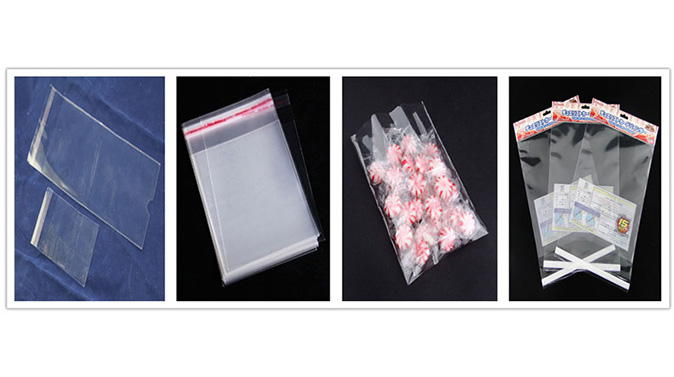

In the packaging industry, the side seal bag making machine plays a crucial role. It is a specialized piece of equipment designed to create bags with seals on the sides. These bags are widely used for packaging various products, from food items to small consumer goods.

The side seal bag making machine operates through a series of well - coordinated steps. First, a roll of packaging material, which could be plastic film, laminated paper, or other flexible materials, is fed into the machine. As the material moves forward, it is shaped into a tube - like structure. The side edges of the tube are then brought together and sealed using heat and pressure. This sealing process fuses the two edges of the material, creating a strong and air - tight seal.

After the side seals are made, the tube is cut into individual bags of the desired length. This cutting operation is usually precise, ensuring that each bag has a consistent size. Some advanced machines can also perform additional operations such as perforating the bags for easy opening or adding printed labels during the bag - making process.

The side seal bag making machine is an essential and versatile piece of equipment in the packaging industry. Its ability to create high - quality, customized bags at a fast pace makes it a valuable asset for businesses across various sectors.

GET A QUOTE